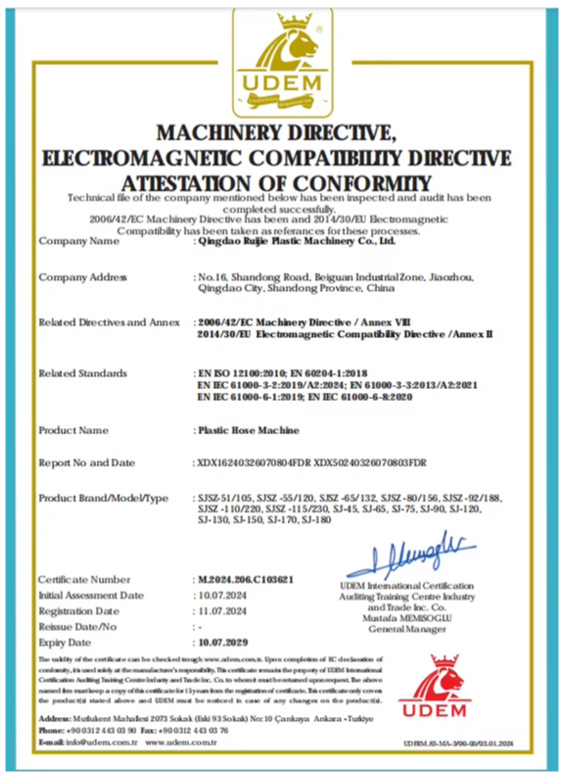

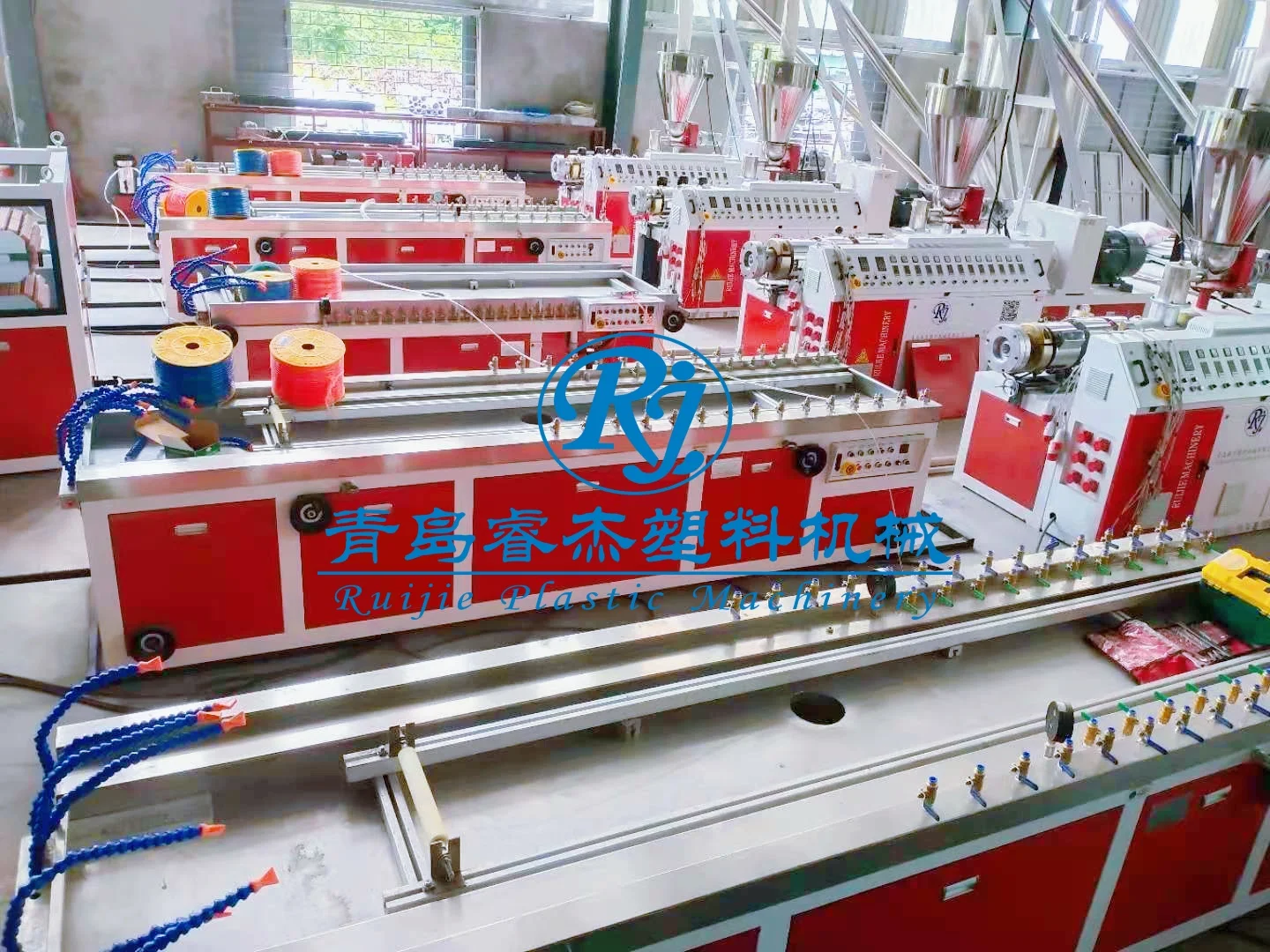

PVC Pipe Processing Machine

This series of extrusion lines is mainly used to produce PVC drainage pipes and U-PVC, and C-PVC water supply pipes.

Advanced design for screws supplies powerful safeguards for the PVC plasticization.

Unique inside oil controlling temperature system adapts different technology formulas.

Beautiful and practical stainless steel body for the vacuum calibration and spray cooling system, the unique multi-section vacuum system ensures stable sizing and cooling for pipes.

Special spray cooling system improves the cooling efficiency.

Special water position and water temperature systems make the machine more intelligent.

The hauling-off unit adopts a pa articular pedrail structure, which is easy and convenient for operation.

Pedrail clamping uses mechanical and pneumatic combining systems, which is more reliable.

The cutting system adopts saw blades and planetary cutting means.

Sumping uses a hydraulic system, which ensures a smooth cross-section.

Equipped with a dust-collecting unit, which ensures a clean working environment.

The Line Components

2. Vacuum calibration tank

3. Hauloff machine

4. Cutting machine

5. Auto stacker

7. Mixer machine, Crusher machine, Miller machine are also optional from your real needs.

Extruder Advantages

1. Double screws feeder.

2. ABB/DELTA inverter, Siemens motors, Siemens contactors.

3. PLC control system is optional.

4. High quality gearbox, screws and barrel.

5. Automatic feeder.

| Model | SJSZ51/105-92/188 |

| Pipe size | 16mm-630mm |

| Material | PVC Resin |

| Main motor | 18.5kw-110kw |

| Cutter | Fixed-length cutting machine |

| Stacker | 4/6 meters length |

Product Usage