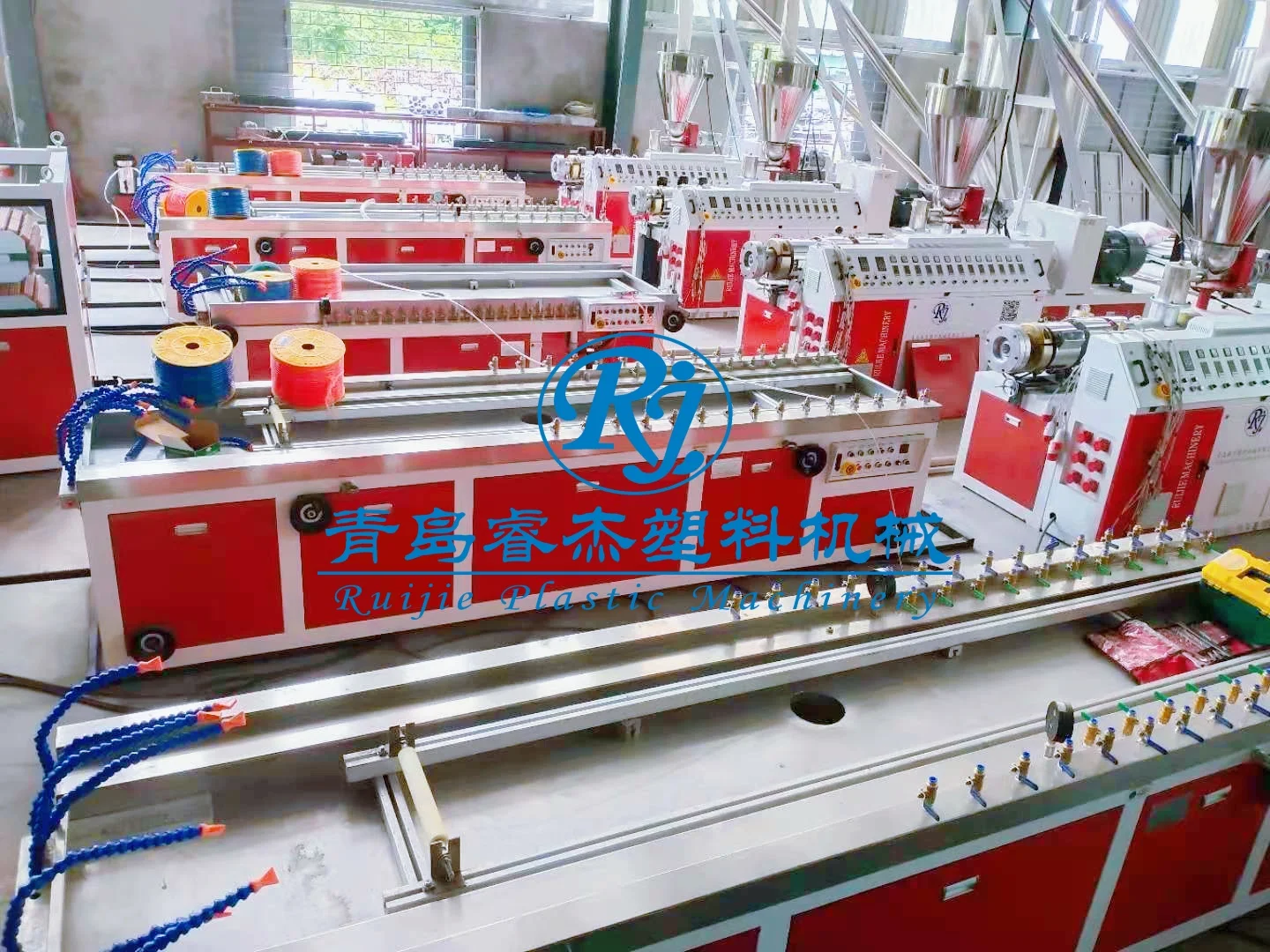

PVC Single Wall Corrugated Hose Extrusion Line, PVC Corrugated Hose Production Machine, PVC Corrugated Hose Machine Line

Easy to change the mold blocks, high speed, stable operation, and high quality of pipe.

The Single-Wall Corrugated Pipe Production Line can produce pipes that are heat-resistant, corrosion-resistant, friction-resistant, and high-strength. These pipes will be used in electrical and pneumatic wire conduits, automotive wire conduits, protection conduits, machine tools, electric locomotives, projection installations, lighting, automatic tools, and other industries. There is significant market demand.

Characteristics and Advantages:

1. The special structural design of the screw and dies, along with the convenience of changing mold blocks, addresses the issues of screw and barrel wear and the difficulties in forming plastic resin.

2. The Corrugator utilizes a closed water cooling structure, a closed block forming chain, and a specially designed rail, ensuring all blocks align correctly and run stably. You won't even see the connecting line on the surface of the pipe. Cooling water circulates within the corrugator, enhancing cooling speed, which significantly increases the pipe production rate. Meanwhile, the corrugator features a modular block design, allowing us to use the same base structure while varying the forming length. The longer the forming length of the corrugator, the higher the pipe output. We can create different corrugator forming lengths to meet diverse customer needs.

Model |

SJ45mm-65mm |

Pipe size |

16mm-250m |

Material |

PP PE granule |

Main motor |

18.5kw-110kw |

Type |

Gear type ,chain type , opitonal |

Speed |

4-25m/min |

The Line Components:

1. Single screw extruder (SJ45-120mm)

2. Die

3. High-speed corrugator

4. Winder or stacker

5. The feeding system is fully automatic

7. Mixer machines and crusher machines are also optional based on your actual needs.

Extruder Advantages:

1. Double screw feeder.

2. ABB/DELTA inverter, Siemens motors, and Siemens contactors.

3. The PLC control system is optional.

4. High-quality gearbox, screws, and barrel.

5. Automatic feeder.