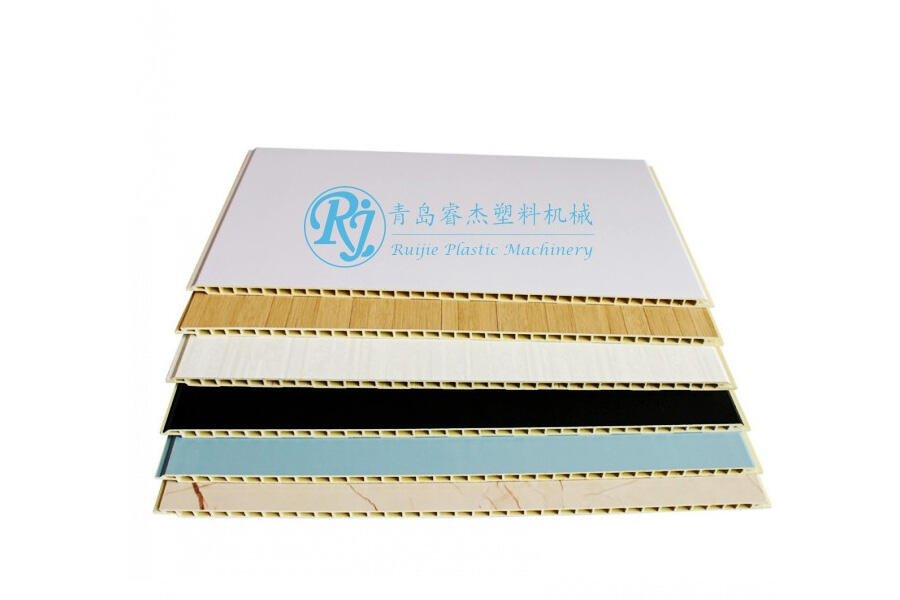

Bamboo Fiber Integrated Wall Panel Production Line

Bamboo fiber integrated wall panel production line:equipment composition, advantages and applications.

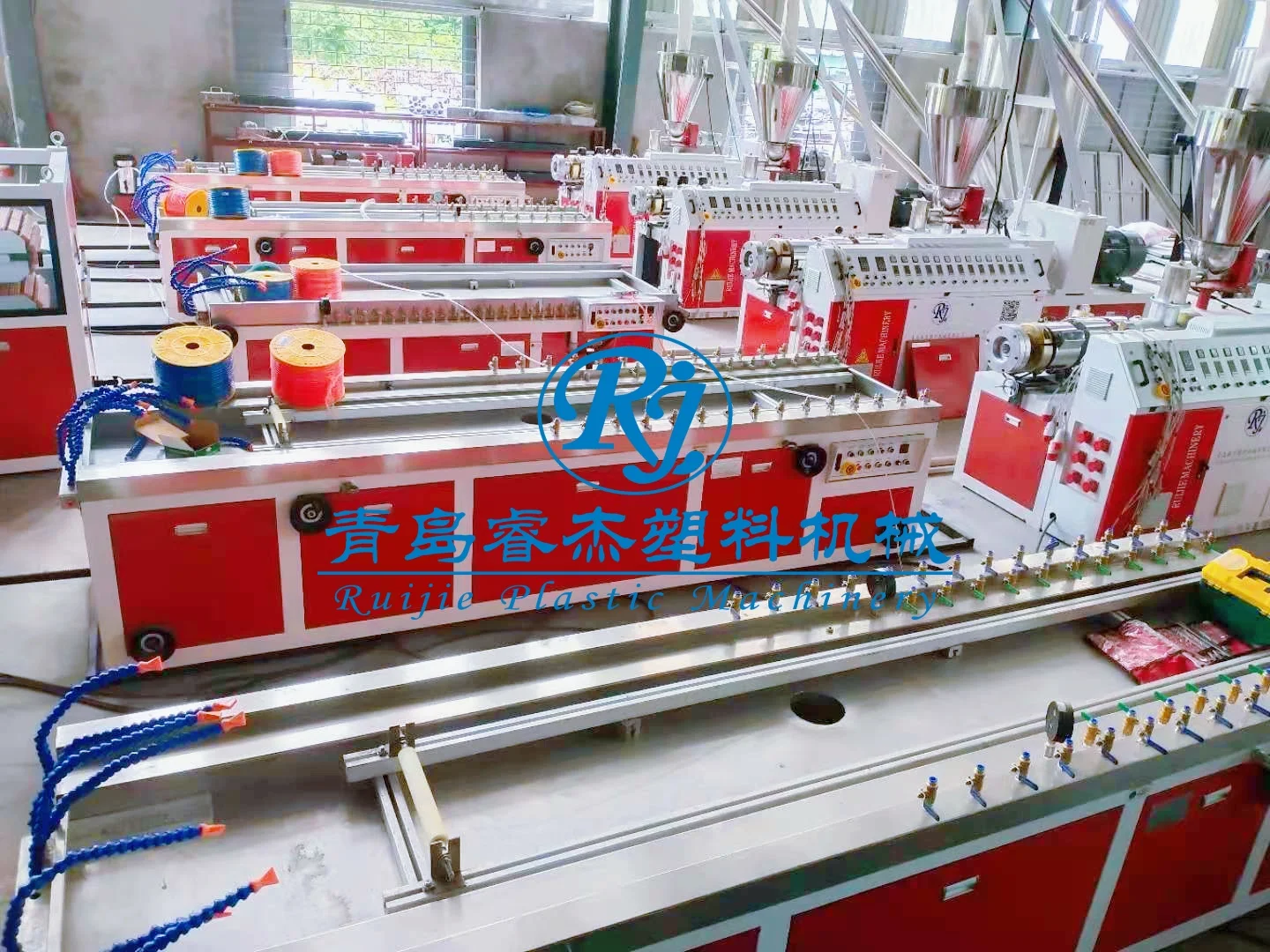

Equipment composition:

Grinding machine, mixer, crusher, conical twin-screw extruder, wallboard mold, wallboard vacuum shaping platform, double crawler traction machine, automatic dust-free cutting machine, automatic unloading and stacking machine. The whole line runs stably, is easy to operate, and has a low failure rate.

Process flow:

PVC processing aids and other raw materials → high-speed mixing → twin-screw extrusion → mold → cooling and shaping → online coating or offline coating process traction cutting → finished product packaging and storage.

Wall production line equipment classification configuration:

- SJSZ51/105 cone double extrusion production line, used to produce smaller lines

- SJSZ 65/132 cone double extrusion production line 300 type, used to produce walls or large lines below 300mm

- SJSZ 65/132 cone double extrusion production line 600 type, used to produce 300-600mm walls

- SJSZ 80/156 cone double extrusion production line 600 type, used to produce 600mm wide boards

- High-speed mixer 300/600 type, 500/1000 type, 800/2500

- Crusher 560 type.

- Grinding mill 600 type

Equipment advantages:

- Newly developed automatic alarm system for lack of material in the feeder box. The feeder has an overload protection system.

- It uses imported electrical control systems such as Delta inverter, Delta temperature controller, Siemens contactor, relay, etc., mechanical transmission systems such as Wafangdian bearings, German imported oil seals, grinding gearboxes, etc. The rubber blocks of the traction machine are made of self-made high-quality, aging-resistant rubber blocks, and the traction machine is equipped with a safety protection baffle.

- The barrel screw adopts a new design concept. With more than 20 years of experience in the industry, different screw designs are adopted according to the different formula ranges of customers to achieve high-quality and efficient extrusion process status.

- The whole line is designed from the perspective of the operator. On the basis of fully understanding the operation process of the integrated wallboard, the inconvenience of the previous equipment in operation is improved, and some common problems in production are easily solved, making the operation and use simpler and more convenient, and easy to control.

Advantages of products:

- The integrated wall has the same processing performance as the log, which can be nailed, drilled, cut, bonded, and connected and fixed with connectors.

- Integrated wall has better physical properties than logs, better dimensional stability than wood, no cracks, warping, no wood knots, no diagonal lines, adding colorants, laminating or composite surface can make various colorful products, so there is no need for regular maintenance.

- Integrated wall has excellent properties such as fireproof, waterproof, corrosion-resistant, moisture-resistant, insect-proof, fungus-free, acid-alkali-resistant, etc., and low maintenance cost.

- Integrated wall has a similar wood appearance during use, higher hardness than logs, longer life, better toughness, high strength, and energy saving. The product is strong, light, heat-insulating, and has a smooth surface.

Product application:

It can be used in a wide range of places, such as indoor homes, hospitals, schools, office buildings, factories, public places, supermarkets, businesses, and arenas.