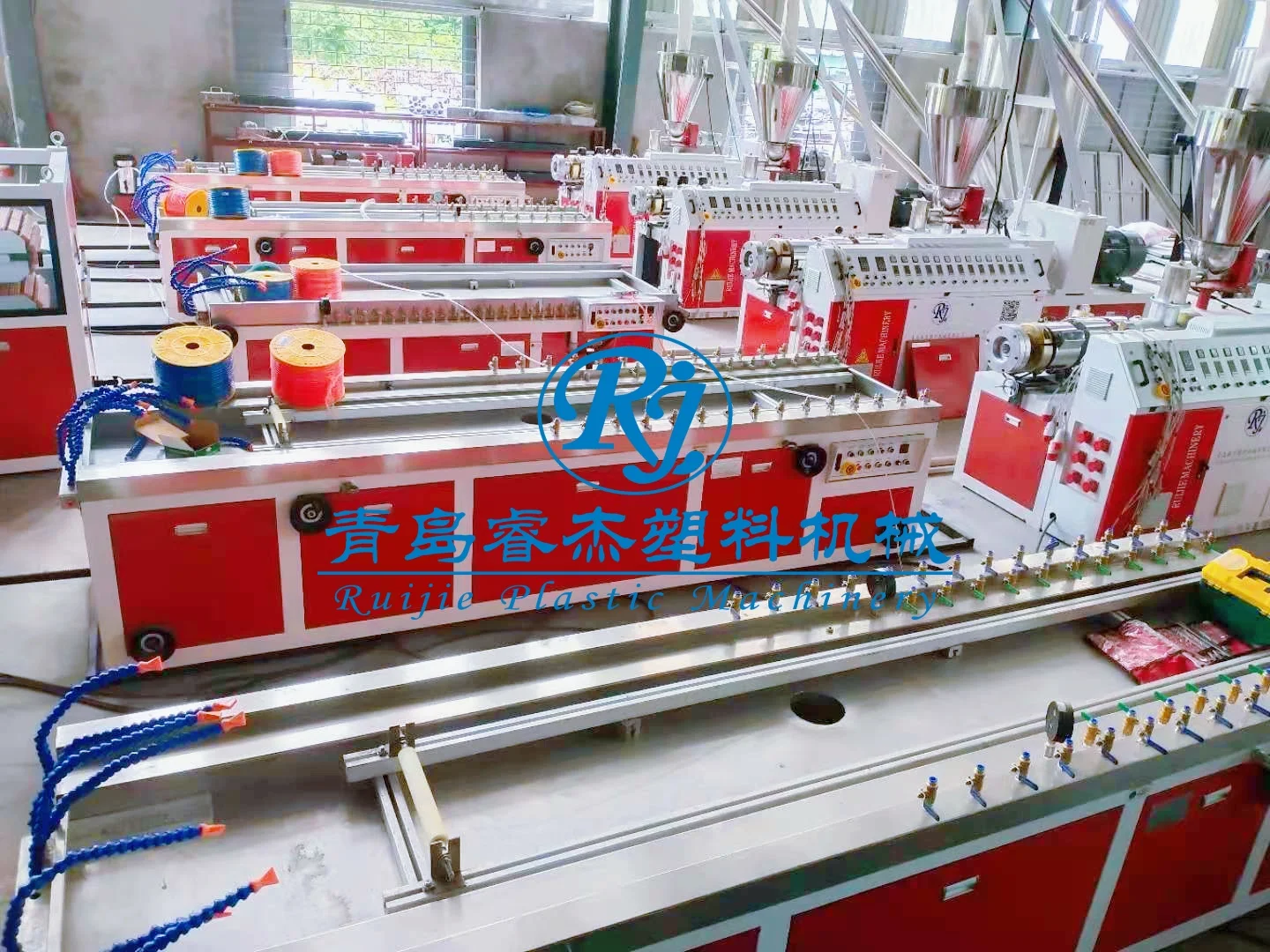

SPC stone plastic floor production line

Equipment composition, advantages and applications.

Equipment composition:

Grinding machine, mixer, crusher, conical twin-screw extruder, floor mold, five-roller shaping, synchronous alignment, bracket, air cooling device, traction machine, cutting machine, fully automatic manipulator palletizing, the whole line runs stably, the operation is simple, and the failure rate is low.

Process flow:

PVC resin powder, calcium powder, stabilizer; stearic acid, etc. raw materials → high-speed mixing → twin-screw extrusion → mold → five-roller shaping → traction cutting → manipulator palletizing - health care - UV treatment - slice connection - slotting - finished product packaging and storage.

- SPC production line equipment classification configuration:

- SJSZ92/188 conical twin-screw extrusion production line

- SJSZ110/220 conical twin-screw extrusion production line

- SJSZ115/230 conical twin-screw extrusion production line

- SJSP136 parallel twin-screw extruder production line

- High-speed mixer 500/1000, 800/2500, 1000/3000, 1500/4500 type

- Crusher 560 type.

- Grinding machine 600 type

Equipment advantages:

- Extruder configuration: Jiangyin General Factory Duoling brand reducer, twin-screw feeding, Siemens electrical appliances, special screw, screw core cooling system.

- Temperature module: Delta PLC temperature control module, small control temperature error, intuitive and easy to understand for operators, one-button heating and full stop, safe and reliable.

- Host control: Operate on a touch screen, each speed can be set independently or synchronously.

- Alarm system: Host high current alarm, host high-speed running material shortage alarm, melt pressure alarm, material level control alarm, etc.

- Anti-blocking mold follow-up system

(1) During operation, when the host is fast, the traction machine will also follow the speed of the extruder. The product will not be blocked or the traction will break the product due to the inconsistency between the extruder speed and the traction speed. If the extrusion speed is fast and the traction is slow, the product will be stuck in the mold and the extruder and the product will be broken.

(2) Fiber optic follow-up system: When the extrusion width of the product exceeds the set value, the traction will automatically speed up. When the product width is lower than the set value, the traction speed will automatically slow down. The acceleration and deceleration values (amplitudes) can be set.

(3) Automatic follow-up software is set in the PLC and touch screen (computer). When the host current is large, the traction will automatically speed up without manual control. The speed problem is automatically solved, just like the automatic cruise of a car, reducing manual labor.

(4) Robot stacking: PLC program controls the stacking of AB stations, and the number of plates at each station can be set independently. When a station is full of plates, the program sends out sound and light signals to prompt the handling.

Product advantages:

- Green and environmentally friendly The main raw material of SPC floor is polyvinyl chloride, which is an environmentally friendly, non-toxic and renewable resource. The main component of SPC lock floor is also added with natural stone powder, which is also a new type of green and environmentally friendly floor decoration material.

- Space saving The thickness of SPC floor is very thin, and the weight per square meter is only about 2-7.5kg. In high-rise industrial buildings, it has incomparable advantages in terms of building load-bearing and space saving.

- Wear-resistant and durable The surface of SPC floor has a special transparent wear-resistant layer processed by high technology, which is very similar to laminate flooring. Its wear-resistant revolution can reach more than 6,000 revolutions, which is very wear-resistant and durable.

- Anti-slip The wear-resistant layer of SPC floor has special anti-slip properties. When it is wet, the foot feels more astringent and it is less likely to fall. That is, the more it encounters water, the more astringent it is.

- Anti-mildew The main component of SPC floor is polyvinyl chloride, which has no affinity with water and will not mold due to high humidity. The surface of the floor has undergone special antibacterial and anti-fouling treatment, which has a strong killing ability against most bacteria and inhibits the ability of bacterial reproduction.

- Easy to install SPC floor has locks on all four sides. Like lock wood floor, it can be installed without glue, which is very convenient and quick.

Product application:

SPC floor is widely used in places such as indoor homes, hospitals, office buildings, public places, supermarkets, businesses, sports venues, etc.