PET/PETG Sheet Production Line

Equipment composition, advantages and applications.

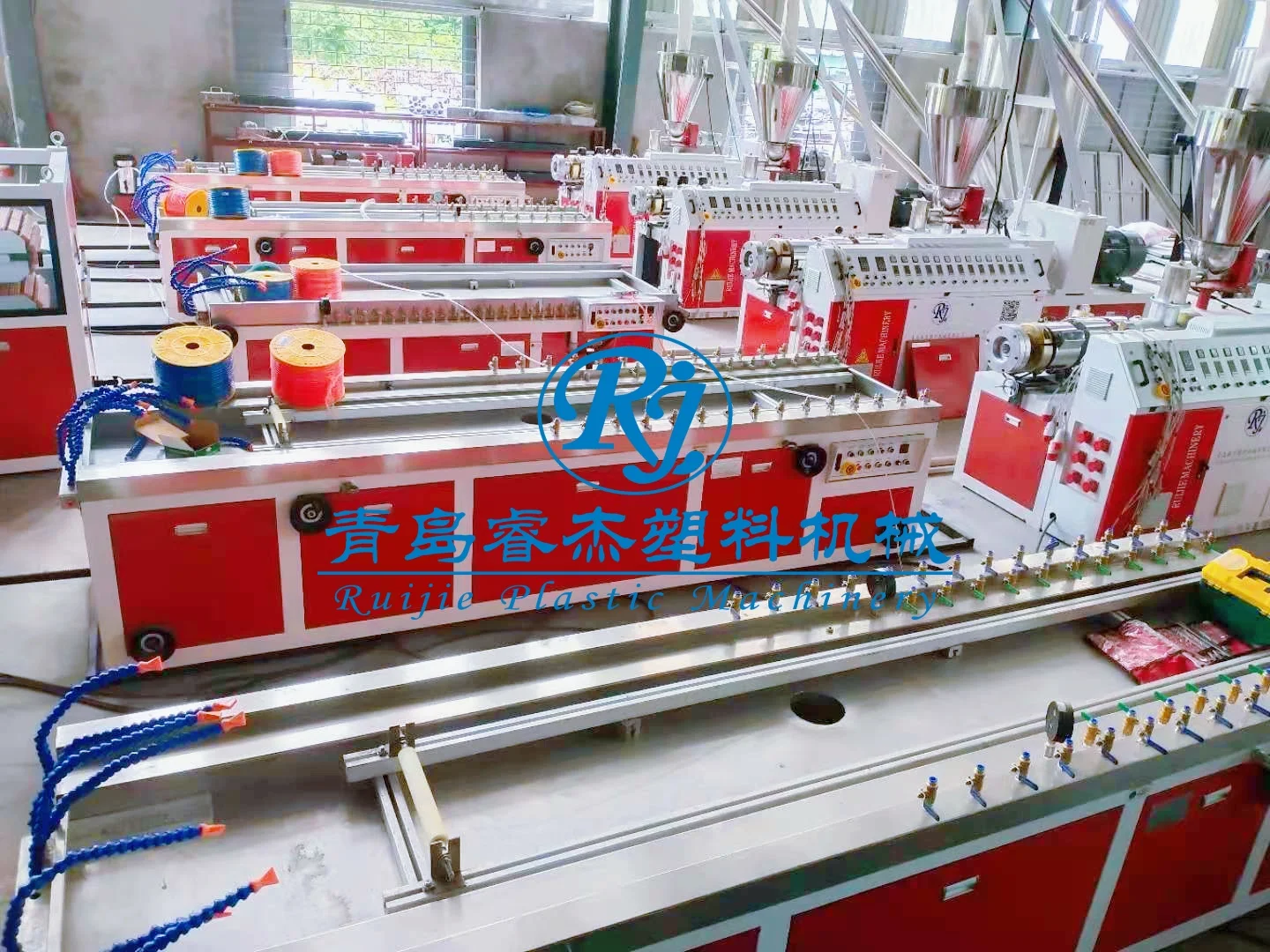

PET Sheet Production Line composition:

- Crystallization drying equipment

- Flat twin extruder or single screw extruder

- Vacuum system

- Screen changer

- Melt metering pump

- Sheet mold

- Three-roll calender

- Temperature controller

- Cooling bracket

- Silicone oil drying device

- Tractor

- Belt storage machine

- Trimming and cutting machine

- Winding machine

Process flow:

This machine is to melt and extrude the sheet after drying and crystallizing the PET bottle flakes and raw materials into the production line. PET-drying crystallization-flat twin extruder-mold-three-roll calender-cooling bracket-silicone oil-tractor-belt storage machine-trimming and cutting machine-winding machine-finished product packaging and storage.

Equipment classification:

- 90 single screw extrusion production line with drying and crystallization equipment.

- 75 flat twin extruder production line without drying and crystallization equipment

- Crusher.

Equipment advantages:

The PET extrusion sheet production line is a new type of sheet production equipment that is free of crystallization and drying. It is developed by our company after years of research and absorption of foreign advanced technologies, integrating multiple production processes and formula systems and consolidating research and development. The three-roll calendering process technology is used to reduce the viscosity of the raw materials, improve the cooling efficiency, and greatly improve the quality and output of the sheets.

The production line has the advantages of green environmental protection and low energy consumption, simple process, convenient operation, compact structure, superior performance, uniform plasticization, stable extrusion, good variety, etc. It is widely used in the fields of fruit, food and various catering packaging.

PET sheets have good barrier properties against oxygen and water vapor, and reliable non-toxic and hygienic properties. They can be used for packaging food, drugs and medical equipment, and can be sterilized by Y-rays. It has good adaptability to environmental protection and can be recycled economically and conveniently. Therefore, PET sheets are considered to be an ideal packaging material that meets environmental protection requirements and are favored by the majority of the blister industry.