LVT Floor Production Line

Equipment composition, advantages and applications.

Equipment composition:

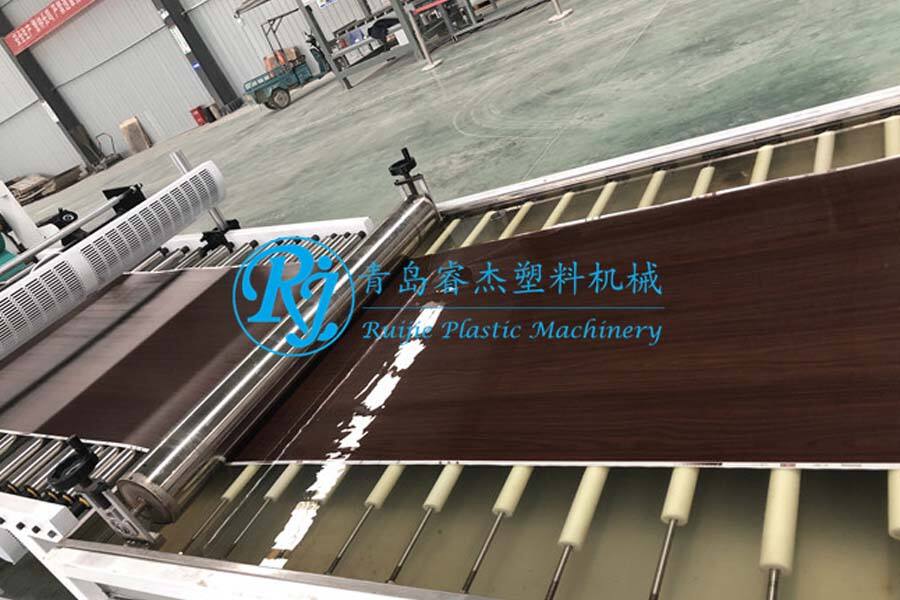

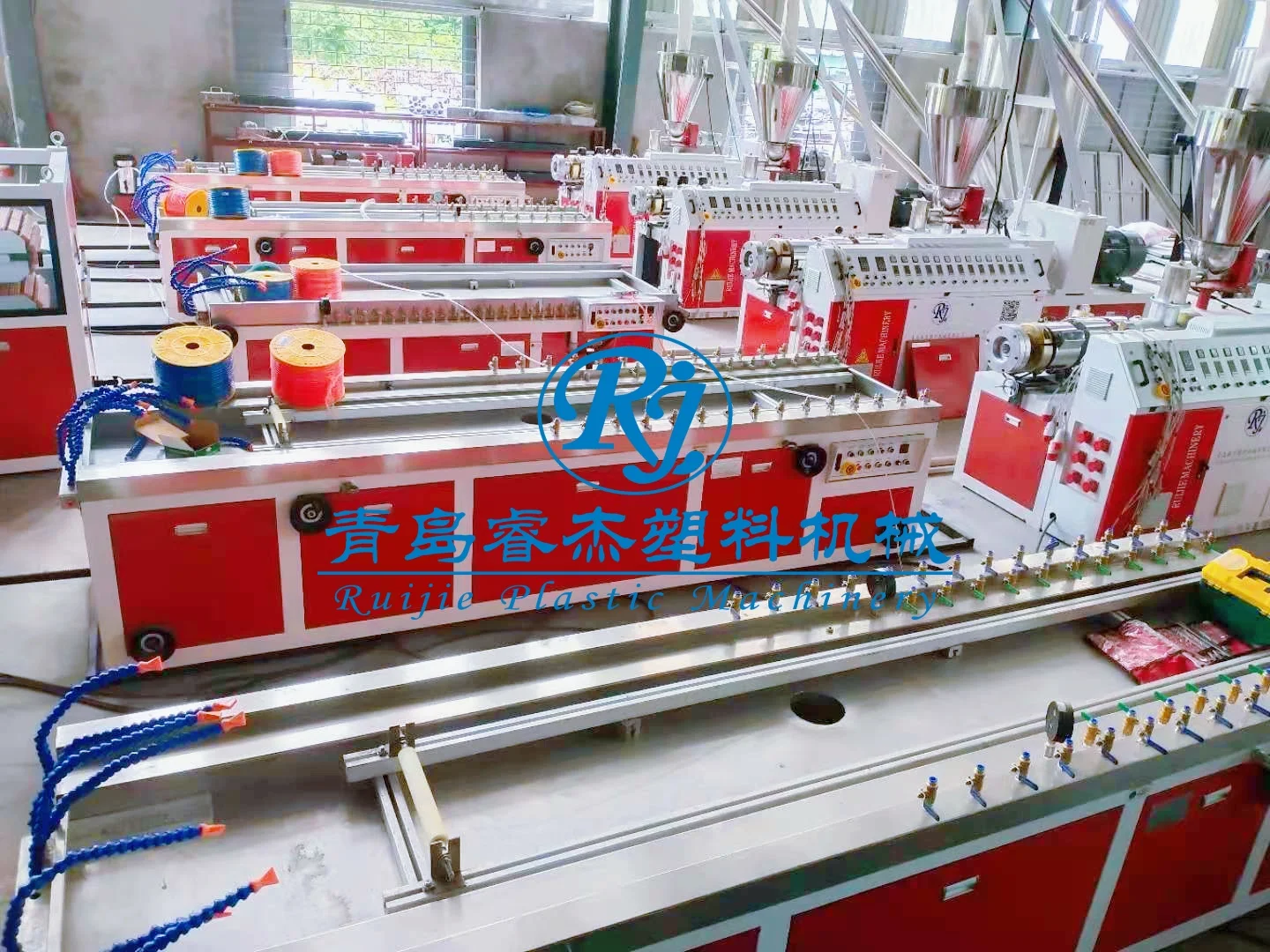

Grinding machine, mixer, crusher, conical twin-screw extruder, mold, four-roller shaping device, bracket, cooling, traction machine, cutting, robot stacking, the whole line runs stably, the operation is simple, and the failure rate is low.

Process flow:

Polyvinyl chloride resin powder, plasticizer, stabilizer, etc. are put into the mixer according to the formula ratio, and the evenly mixed raw materials are put into the extruder for heating and plasticization. The raw materials enter the four-roll calender, and are formed after calendering, cooled, stacked by the robot, cured, punched, glued, and the finished products are packaged and stored.

- LVT production line equipment classification equipment:

- SJSZ 80/156 cone double extrusion production line, used to produce LVT floors of various thicknesses

- High-speed mixer 300/600, 500/1000, 800/2500

- Crusher 560

- Grinding machine 600

- Manual punch or automatic punch

- Glue machine

Equipment advantages:

- Newly developed automatic alarm system for lack of material in the feed box of the feeder. The feeder has an overload protection system.

- It uses imported electrical control systems such as Delta inverter, Delta temperature controller, Siemens contactor, relay, etc., mechanical transmission systems such as Wafangdian bearings, German imported oil seals, grinding gearboxes, etc. The rubber blocks of the traction machine are made of self-made high-quality, aging-resistant rubber blocks, and the traction machine is equipped with a safety protection baffle.

- The barrel screw adopts a new design concept. With more than 20 years of experience in the industry, different screw designs are adopted according to the different formula ranges of customers to achieve high-quality and efficient extrusion process status.

- The whole line is designed from the perspective of the operator. On the basis of fully understanding the operation process of the integrated wallboard, the inconvenience of the previous equipment in operation is improved, and some common problems in production are easily solved, making the operation and use simpler and more convenient, and easy to control.

Advantages of products:

The recognized advantages of LVT flooring are: cheap, environmentally friendly, wear-resistant, elastic and impact-resistant, waterproof and flame-retardant, waterproof and moisture-proof, and easy to maintain. This kind of floor is often laid in schools, kindergartens, playrooms, and also used in children's rooms at home.

Product application:

LVT flooring, soft and flexible elastic flooring, professionally described as "semi-rigid sheet plastic flooring", they can even be bent into rolls, the market retail price of LVT flooring ranges from tens of yuan to two hundred yuan, and was previously mainly used in industrial projects. Because it has high requirements for the floor, it requires professionals to lay it, so from a cost perspective, it is usually only suitable for large-area laying. Of course, for rental houses or offices that do not require high flatness, this kind of flooring is both beautiful and practical.