PVC Floor Leather Production Line

Equipment composition, advantages and applications.

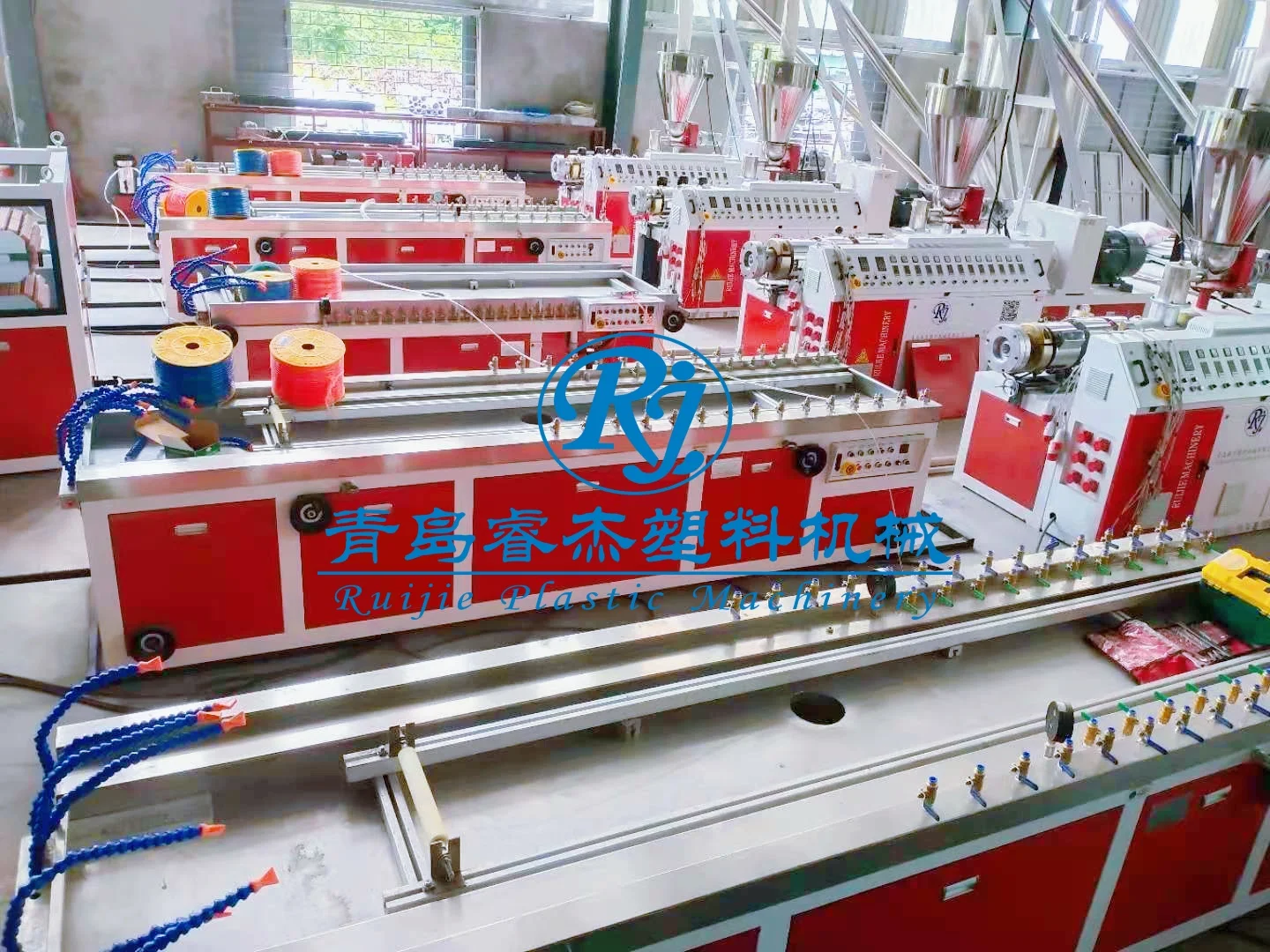

Equipment composition:

Grinding mill, mixer, crusher, conical twin-screw extruder, mold, three-roller shaping machine, bracket, wire storage device, traction machine, cutting machine, friction winding machine. The whole line runs stably, the operation is simple, and the failure rate is low.

Process flow:

PVC resin powder, calcium powder, stearic acid, paraffin, stabilizer and other raw materials → high-speed mixing → twin-screw extrusion → mold → three-roller cooling shaping → traction cutting → finished product packaging and storage.

Floor leather production line equipment classification configuration:

SJSZ 92/188 conical twin extrusion production line

High-speed mixer 500/1000 type, 800/2500

Crusher 560 type.

Grinding mill 600 type

Equipment advantages:

- Newly developed automatic alarm system for lack of material in the feed box of the feeder. The feeder has an overload protection system.

- It adopts imported electrical control systems such as Delta inverter, Delta temperature controller, Siemens contactor, relay, etc., mechanical transmission systems such as Wafangdian bearing, German imported oil seal, grinding gearbox, etc. The rubber block of the traction machine adopts self-made high-quality and aging-resistant rubber block, and the traction machine is equipped with a safety protection baffle.

- The barrel screw adopts a new design concept. With more than 20 years of experience in the industry, different screw designs are adopted according to the different formula ranges of customers to achieve high-quality and efficient extrusion process state.

- The whole line is designed from the perspective of the operator. On the basis of fully understanding the operation process of integrated wall panels, the inconvenience of previous equipment in operation is improved, and some common problems in production are easily solved, making the operation and use simpler and more convenient, and easy to control.

- The production line has a simple structure and is easy to operate. Different equipment components can be configured according to customer requirements to produce single-layer and multi-layer composite products. Unwinding devices can also be added to produce internal reinforcement products, composite non-woven products and PVC decorative films, etc.

Product advantages:

PVC floor leather has the properties of wear resistance, corrosion resistance and flame retardancy, and is widely used in locomotives, hotels, entertainment exhibitions and families.

Product application:

Single-layer and multi-layer floor leather is widely used in automobile interiors, trains, airports, hotels and other public places, as well as home decoration. PVC floor leather can also be used as a roll material in engineering fields such as tunnel drainage, foundation moisture prevention, roof leakage prevention, and landfill.